At the recent 6th GBA Robotics and Artificial Intelligence Conference, the "2024 Guangdong Robot Industry Development Report" (hereinafter referred to as the Report) was released. The Reportpointed out that Guangdong has become the largest agglomeration area for the intelligent robot industry in China, leading in both industry scale and the number of enterprises, nurturing and introducing a group of leading enterprises and specialized and high-tech firms in various links of the robot industry chain.

It is noted that in 2024, Guangdong's annual output of industrial robots exceeded 240,000 sets, accounting for 44% of the country's total and ranking first for five consecutive years.After decades of development, Guangdong Province has become China's largest intelligent robot industry agglomeration area, and each city has its own characteristics in distinct robotics subfields.

For example, Shenzhen has focused on developing industrial robots and integrated applications mainly for the 3C (computer, communication, and consumer electronics) industry, industrial robot body, and core components manufacturing. The city is also in a leading position in industries closely related to robot technology, such as humanoid robots, drones, and new energy vehicles.

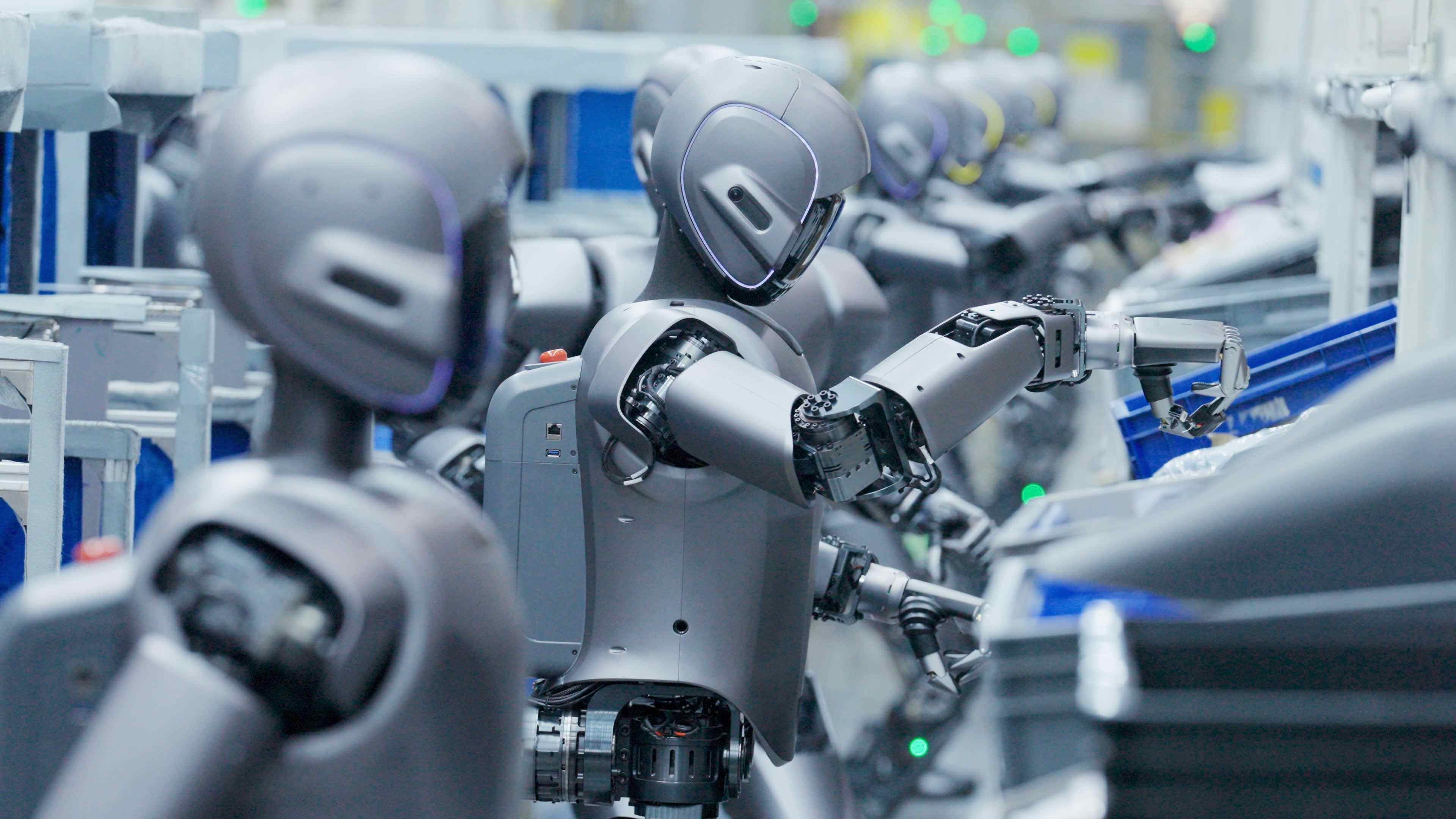

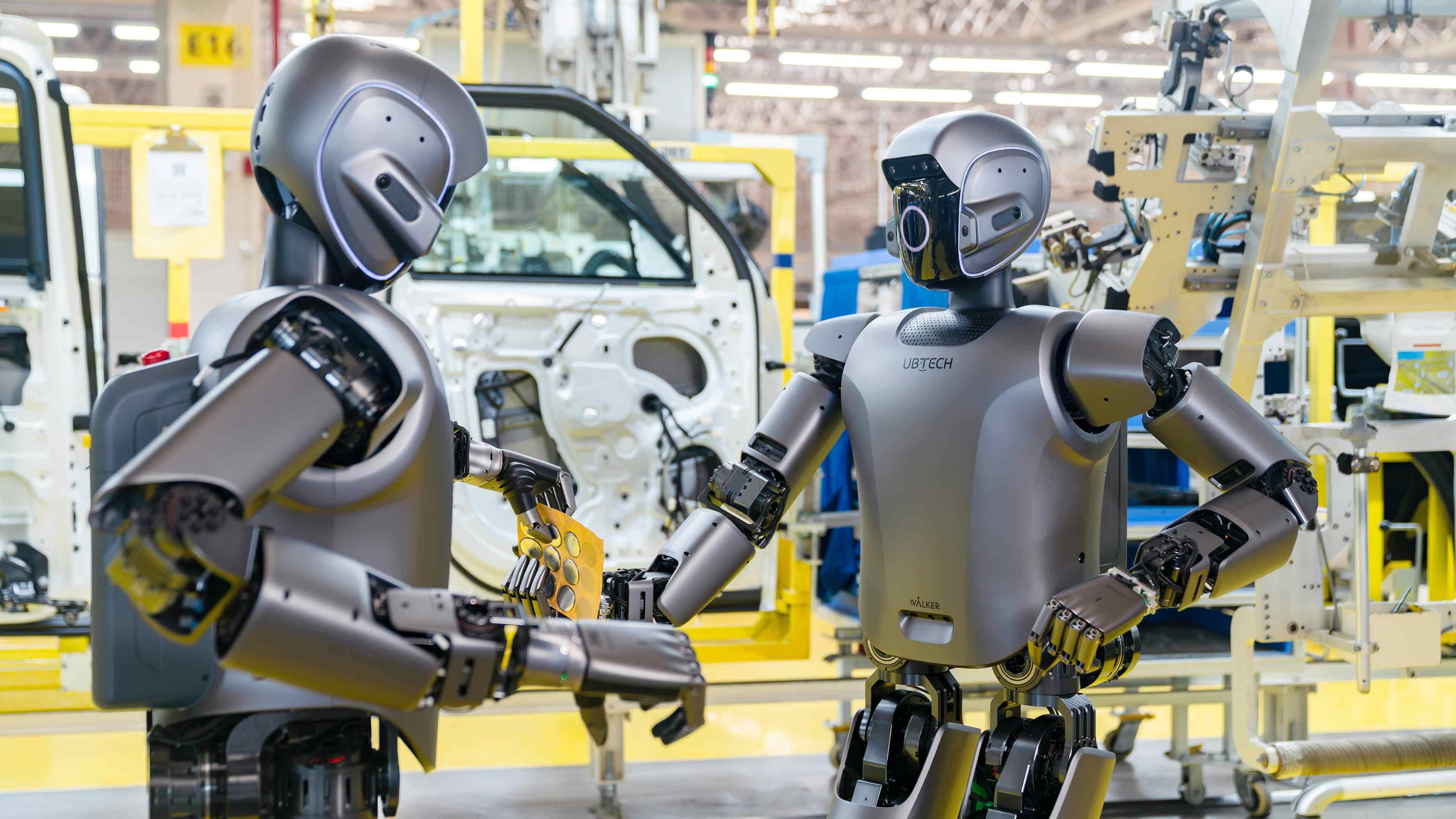

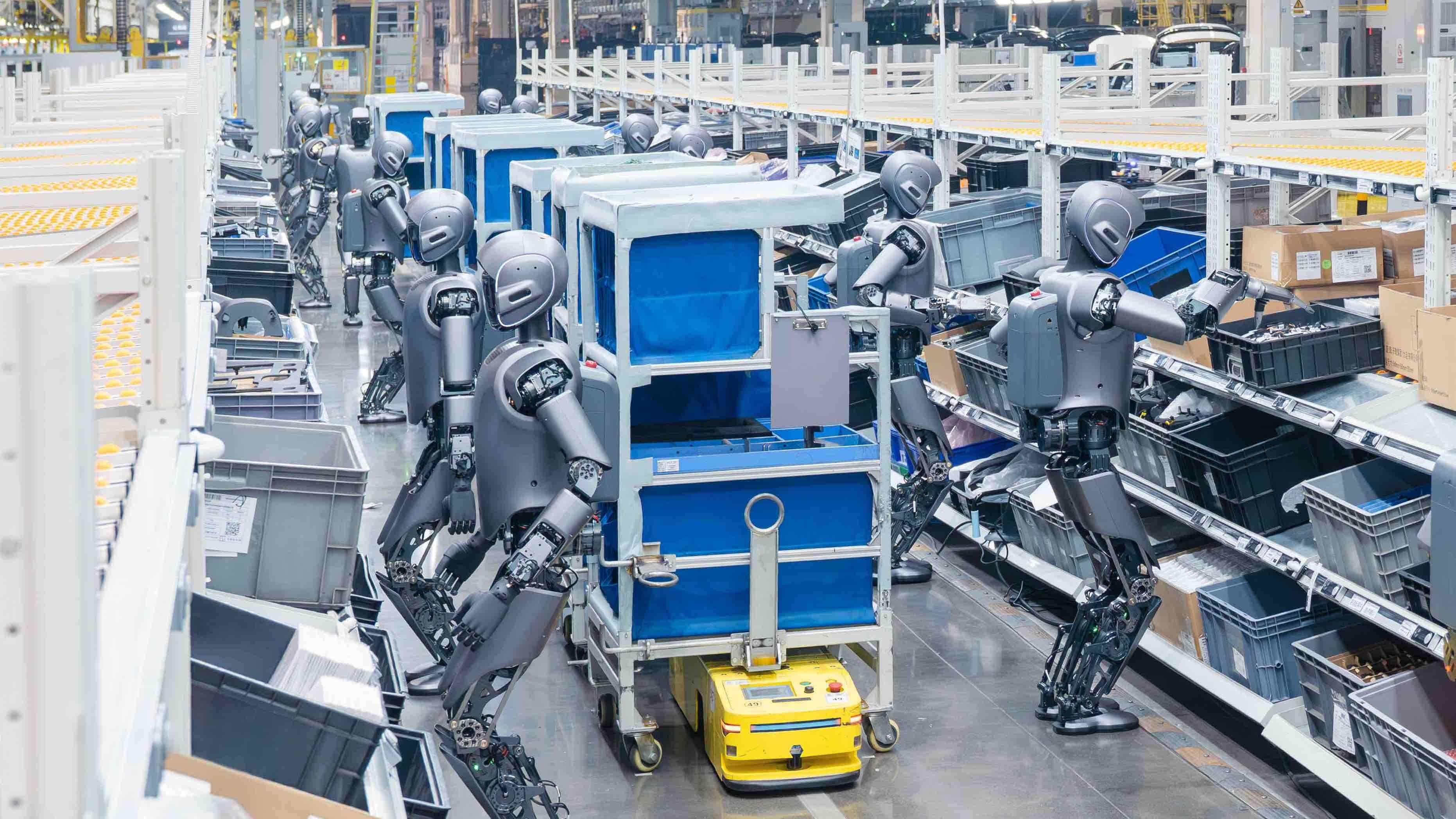

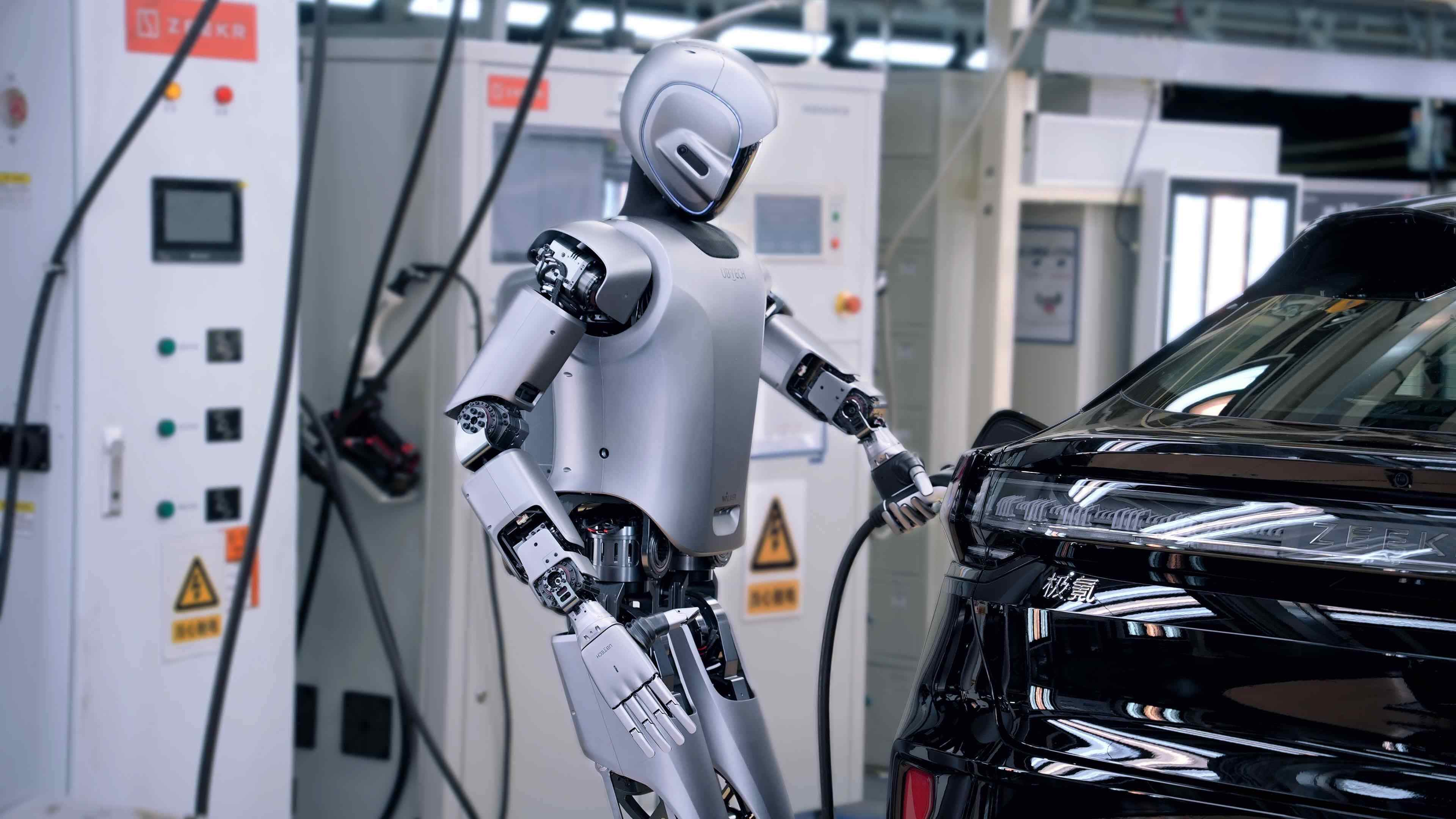

Recently, a well-known tech enterprisecalled UBTECH Robotics in Shenzhen conducted the world's first humanoid robot collaborative training with multiple robots operating across various scenarios and tasks at the Zeekr 5G Smart Factory. Thetrainingaims to establish a general humanoid robot swarm solution formulti-task industrial scenarios and drive the evolution of humanoid robots from stand-alone autonomy to swarm intelligence.

During the training, UBTECH introduced swarm intelligence into the humanoid robot field for the first time, enabling coordinated multi-robot tasks. By using clusters of humanoid robots as physical carriers, UBTECH explores high-level embodied intelligence through intensive interaction between group behavior and the external physical environment. To achieve this, UBTECH developed the BrainNet software architectureand designed the Internet of Humanoids (IoH), a humanoid intelligent network hub, providing a replicable track forsoftware and hardware with swarm intelligence.

Looking ahead, in complex scenarios, swarm intelligence—emerging from dynamic interactions and collaboration among distributed individuals—can enable humanoid robots to make efficient decisions andadapt to changing conditions and large-scale commercial applications across multiple scenarios and tasks.This breakthrough not only provides a reference model for the application of humanoid robots in intelligent manufacturing but will also facilitate new industrialization transiting from "semi-flexible manufacturing" to "fully flexible intelligent manufacturing".

Up to now, UBTECH has already established partnerships with multiple leading enterprises, such as Dongfeng Liuzhou Motor, Foxconn, and SF Express. Its self-developed Walker S series of industrial humanoid robots have entered more automobile factories than any other humanoid robots worldwide and have completed the first phase of stand-alone autonomous intelligence training.

Source: Lingnan On the Cloud

广东机器人产业领跑全国,深圳人形机器人引入群体智能

近日,第六届粤港澳机器人与人工智能大会在广州举行,现场发布的《2024年广东省机器人产业发展报告》(以下简称《报告》)指出,广东已成为中国最大的智能机器人产业聚集区,产业规模、企业数量均居中国首位,在智能机器人产业链各环节培育引进了一批龙头骨干企业和专精特新企业。

记者注意到,2024年,广东的工业机器人年产量超24万套,占全国44%,连续5年居全国第一。据悉,经过数十年的发展,广东省已成为中国最大的智能机器人产业聚集区,各地在机器人赛道上各有特点。

譬如,深圳推动以面向3C产业为主的工业机器人及集成应用,发展工业机器人本体及核心零部件制造,在人形机器人产业、无人机、新能源汽车等与机器人技术密切相关产业也处于领先地位。

近日,深圳知名科技企业优必选在极氪5G智慧工厂开展全球首例多台、多场景、多任务的人形机器人协同实训,探索建立面向多任务工业场景的通用人形机器人群体作业解决方案,推动人形机器人从单机自主向群体智能进化。

此次实训中,优必选首次将群体智能技术引入人形机器人领域,实现多机协同作业。以人形机器人集群为物理载体,探索通过群体行为与外部物理环境密集交互而进化出的高阶具身智能。为此,优必选创新提出了人形机器人群脑网络(BrainNet)软件架构,并设计人形智能网联中枢Internet of Humanoids(IoH),为群体智能的软硬件实现提供了可借鉴的路径。

展望未来,在复杂场景下,群体智能通过分布式个体的动态交互与协同,涌现出超越单一能力的全局智慧,能够帮助人形机器人高效决策与自适应优化,突破跨场景跨任务的大规模商业化应用。这一突破不仅为人形机器人在智能制造中的规模化应用提供了参考范式,也将推进新型工业化从“半柔性制造”向“全柔性智造”的范式跃迁。

目前,优必选已与东风柳汽、吉利汽车、一汽-大众青岛分公司、奥迪一汽、比亚迪、北汽新能源、富士康、顺丰等多家行业领军企业达成合作,自主研发的工业人形机器人Walker S系列已成功进入全球最多车厂,并完成了第一阶段的单机自主智能实训。

文丨记者 许张超 沈婷婷

图丨受访者提供

翻译丨盛嘉

审校丨郑圣浩

-

Poster|Spring at Shaoguan University: A Blossoming Cherry Wonderland

2025-03-04 21:53:48 -

iSeeChina | U.S. student talks with NPC Deputy & Midea CFO Zhong Zheng: 'China's stunning AI growth!'

2025-03-04 19:56:37 -

Poster | Million Talents to South China Plan

2025-03-04 11:48:32 -

Poster|China's top political advisory body holds press conference ahead of annual session

2025-03-04 11:48:37