Recently, the 2024 Guangdong Science and Technology Awards were announced, with the project titled "Key Technologies and Equipment Development for the Construction of Ultra-Wide Deep-Buried Steel-Shell Concrete Cross-Sea Immersed Tunnels" winning the Special Award for Scientific and Technological Progress. Applied to the construction of the undersea tunnel of the Shezhen-Zhongshan Link, this achievement has overcome multiple world-class challenges and has set several world records.

The undersea tunnel of the ShenZhong Link stretches 6,845 meters in total length, making it the world's longest and widest undersea steel-shell concrete tube tunnel. As a cross-sea cluster project integrating "bridges, islands, tunnels, and underwater interchanges," the ShenZhong Link has achieved multiple world records, with the most impressive one being the world's longest and widest undersea steel-shell immersed tube tunnel. Yet the construction journey confronted a series of world-class challenges from the very beginning.

The key to solving these challenges lies in the project "Key Technologies and Equipment Development for the Construction of Ultra-Wide Deep-Buried Steel-Shell Concrete Cross-Sea Immersed Tunnels." Wu Yugang, former deputy chief engineer of Guangdong Provincial Communications Group Co., Ltd., vividly compares the structural configuration of the ultra-wide, deep-buried steel-shell concrete immersed tube sections to a "sandwich," where inner and outer steel plates form a compartment filled with concrete. This structure not only significantly enhances load-bearing capacity and durability but also fills a gap in international technology in this field, saving over 900 million yuan in construction costs compared to traditional solutions.

In Wu's view, the emergence of multiple "world firsts" would not have been possible without Guangdong's solid industrial foundation. The project relied on the shipbuilding base in Guangdong for steel-shell fabrication, which in turn drove upgrades to its production lines and technological iteration, creating a virtuous cycle where "the project advances the industry, and the industry feeds back into the project." Today, the technological achievements of the ShenZhong Link are naturally extending to similar projects and other fields through universities, research institutes and manufacturing enterprises involved, providing valuable experience that can be replicated and promoted.

多项“世界首创”成就跨海超级工程

近日,2024年度广东省科学技术奖揭晓,“超宽深埋钢壳混凝土跨海沉管隧道建设关键技术与装备研发”项目斩获科技进步奖特等奖。该项目成果应用于深中通道海底隧道建设,攻克了多项世界级难题,创下多项世界纪录。

深中通道海底隧道全长6845米,是目前世界上最长、最宽的海底钢壳混凝土沉管隧道。作为集“桥、岛、隧、水下互通”于一体的跨海集群工程,深中通道创下了多项世界之最。其中最惊艳的,就是世界最长、最宽的钢壳海底沉管隧道。而它的建设之路,从起步起就直面一系列世界级难题。

破解这些难题的关键,正是“超宽深埋钢壳混凝土跨海沉管隧道建设关键技术与装备研发”项目。广东省交通集团有限公司原副总工程师吴玉刚形象地将超宽深埋钢壳混凝土沉管管节结构型式比喻为“三明治”结构——内外双层钢板形成隔舱,中间灌注混凝土。该结构不仅有效地提高了结构承载能力和耐久性,更填补了国际相关领域技术空白,相比传统方案节约造价超过9亿元。

在吴玉刚看来,多项“世界首创”的诞生,离不开广东坚实的产业基础。项目依托广州造船基地完成钢壳制造,也倒逼其生产线升级与技术迭代,形成“项目带动产业、产业反哺项目”的良性循环。如今,深中通道的技术成果正通过参与项目的高校、科研机构及制造企业,自然辐射至类似工程及其他领域,成为可复制、可推广的宝贵经验。

文丨郭思琦 张小悦

译丨盛嘉

英文审校丨赵凡

-

Why is Shenzhen seen as 'dream factory' for high-tech enterprises?In Shenzhen, a vibrant rainforest-like innovation ecosystem is taking shape.2025-11-22 21:51:12

Why is Shenzhen seen as 'dream factory' for high-tech enterprises?In Shenzhen, a vibrant rainforest-like innovation ecosystem is taking shape.2025-11-22 21:51:12 -

Guangdong-Hong Kong-Macao forge new era through collaborationA new era for sports in the Greater Bay Area (GBA)2025-11-22 21:51:12

Guangdong-Hong Kong-Macao forge new era through collaborationA new era for sports in the Greater Bay Area (GBA)2025-11-22 21:51:12 -

Five highlights of 15th National Games: technology, unity, engagement, security and innovationOn November 21st, the 15th National Games concluded in Shenzhen.2025-11-22 21:51:12

Five highlights of 15th National Games: technology, unity, engagement, security and innovationOn November 21st, the 15th National Games concluded in Shenzhen.2025-11-22 21:51:12 -

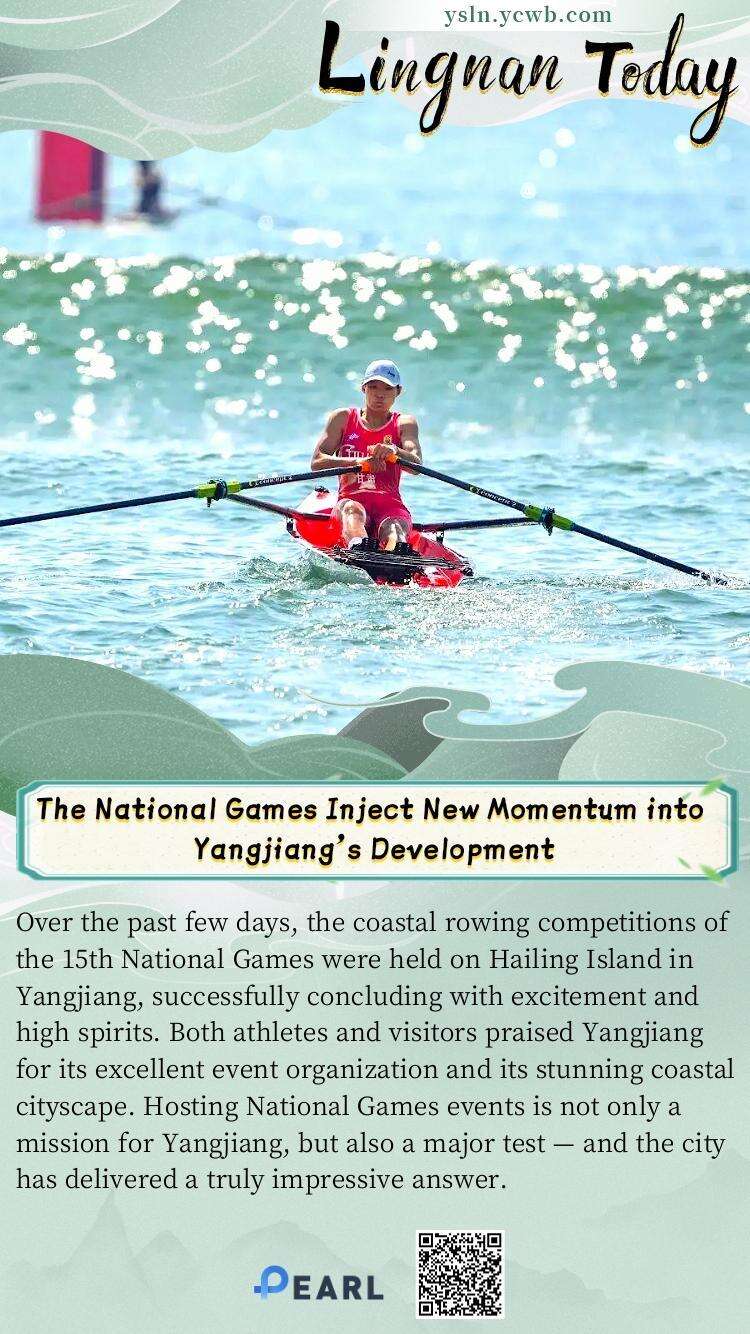

Poster丨The National Games Inject New Momentum into Yangjiang's Development2025-11-21 21:28:21

Poster丨The National Games Inject New Momentum into Yangjiang's Development2025-11-21 21:28:21