With the upcoming Dragon Boat Festival, the rivers of Guangzhou have come alive with vibrant dragon boats of all sizes. The rhythmic beats of drums fill the air as the athletes train vigorously, slicing through the water's surface in preparation for the upcoming dragon boat races. This year's resurgence in dragon boat activities has also ignited a fervor for dragon boat making, leading to a surge in orders at the century-old shipyard in Shangjiao Village.

Shangjiao Village is the oldest dragon boat manufacturing base in Guangdong, with a history of handcrafted shipbuilding spanning over 140 years. Many of the traditional dragon boats that compete in the spirited races among villages and communities in Guangzhou during the Dragon Boat Festival are crafted here. Over the years, Shangjiao Dragon Boat Shipyard has not only become a leading industry player in dragon boat production in the Pearl River Delta region but has also seen its dragon boats sold to Hunan, Zhejiang, Hong Kong, Macao, and Southeast Asian countries. The traditional craftsmanship of Shangjiao dragon boat making has even been recognized as an intangible cultural heritage of Guangdong Province.

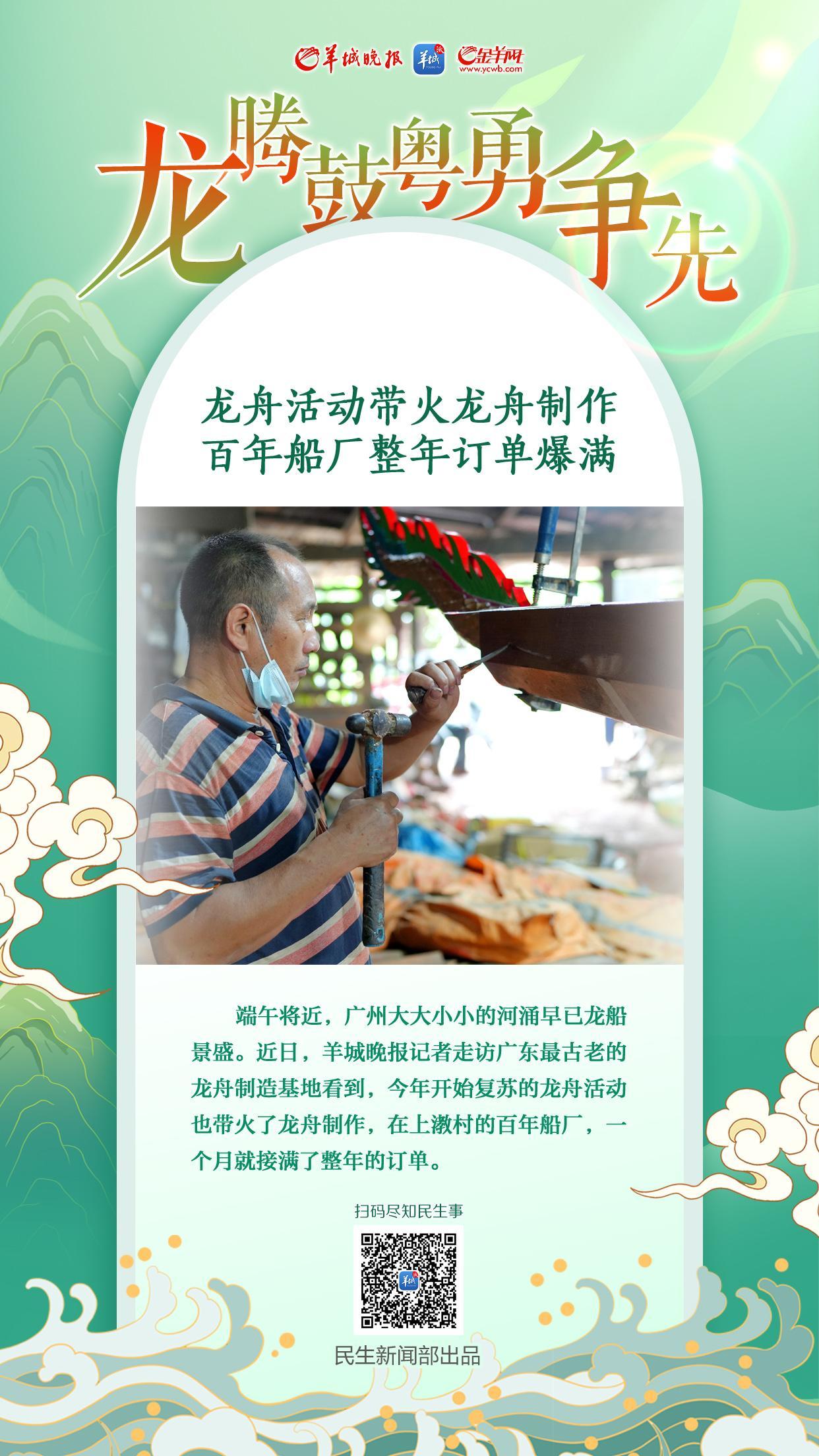

Huang Jianting, born into a shipbuilding family, grew up next to the shipyard, where he absorbed the art of dragon boat making from his elders. Taking over the shipyard from his predecessors, he now represents the fifth generation of Shangjiao's dragon boat-making heritage.

Using Belian wood and fir wood, the construction of a dragon boat encompasses eight major processes, including constructing the frame of the boat by assembling the planks, joining them at the bow and stern using stainless steel screws, using clamps to hold the planks together during assembly, cutting plywood sheets to create the bottom of the boat and securing them to the frame using screws, cutting and attach plywood sheets to create the sides of the boat, securing the plywood with screws, reinforcing the joints with ropes, and sanding the entire boat to achieve a smooth surface and applying multiple coats of marine-grade varnish or paint to protect the wood and enhance its appearance. Further subdivisions reveal nearly 100 meticulous steps. Currently, Huang Jianting's shipyard employs 12 workers. He explains, "Even with the assistance of modern equipment, it takes about 20 days for 10 workers to complete a traditional 40-meter-long dragon boat, and around 10 days for shorter 20-meter-long dragon boats. Refurbishing a dragon boat also takes about 10 days, or even a week if it's a quick renovation."

Among the dozen or so new boats being crafted this year, the most meaningful one in Huang Jianting's eyes is the 40-meter-long "Tuhua" (Soil and Splendor) dragon boat. This dragon boat belongs to the Tuhua Village in Haizhu District. Huang Jianting shares, "The first dragon boat in their village was made by my grandfather and has won awards in various dragon boat races in Guangzhou. Years later, having the opportunity to craft another dragon boat for them is something I consider incredibly meaningful."

龙舟活动带火龙舟制作,百年船厂整年订单爆满

端午将近,广州大大小小的河涌早已龙船景盛,阵阵鼓声响起,健儿们在宽阔的水面劈波斩浪,积极训练备战龙舟赛事。今年开始复苏的龙舟活动也带火了龙舟制作,在上漖村的百年船厂,一个月就接满了整年订单。

上漖村是广东最古老的龙舟制造基地,手工造船历史已有140多年。每年端午节前后,广州各村社间争流竞渡的传统龙舟多数出自这里。经过多年发展,上漖龙船厂不仅成为珠三角地区龙舟制作的行业龙头,龙舟制作的订单更是远销至湖南、浙江、港澳及东南亚地区,上漖龙舟制作技艺也被列入广东省非物质文化遗产。

黄剑挺出生在造船世家,自幼在船厂旁边长大,从小耳濡目染父辈制作龙舟,从父辈那里接手船厂,如今的他,已是上漖龙舟制作技艺第五代传承人。

造龙舟一般选用坤甸木和杉木,整个过程分为八大工序,包括扎底骨、制脚旁、上大旁、扎彩盘、钉花旁、钉夹旁、扎龙缆、上油打磨等,再细分则差不多有100道小工序。目前,黄剑挺的船厂有12个工人,他介绍,“即使在现代设备的帮助下,传统40米长的龙舟,10个工人大概需要20天才能做好一条,一些20米长的短龙舟,大概需要10来天。翻新一条龙舟也要10天左右,快的可能一个星期。”

在黄剑挺心目中,今年制作的十几条新舟里,40米长的“土华号”最有意义。这条龙舟属于海珠区土华村,黄剑挺介绍,“他们村里的第一条龙舟是我爷爷做的,也在广州各龙舟赛得过奖。经过这么多年,有机会帮他们再制作一条龙舟,我认为是一件非常有意义的事情。”

文|羊城晚报全媒体记者 徐振天

视频拍摄、图|羊城晚报全媒体记者 徐振天 徐炜伦

视频剪辑|羊城晚报全媒体记者 范晗越 黎杰文

海报|肖莎

翻译|刘佳慧

责编|王瑜瑛